Features and advantages

● Good shock absorption

● Simple maintenance

● High rigidity

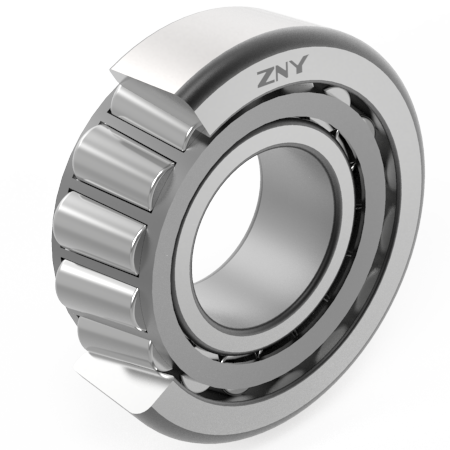

Tapered Roller Bearings: The design features the inner and outer ring raceway surfaces and the cone apexes of the rollers converging at a single point on the bearing's central axis. The truncated cone-shaped rollers, serving as the rolling elements, are assembled in the bearing, guided by the large edge of the inner ring.

They can withstand radial loads and unidirectional axial loads. When a load is applied, it generates an axial component of force, so like angular contact ball bearings, they are typically used in pairs or must be used in a double-row bearing configuration. In this case, the appropriate internal clearance can be set by adjusting the space between the inner and outer rings.

As they are separable, the inner and outer rings can be disassembled separately.

For high-load capacity, there's the HR series with increased roller size and number.

Depending on the contact angle size, they are classified into normal, medium, and large cone angle bearings. Based on the number of roller rows, they can be divided into double-row and four-row tapered roller bearings. Generally, steel plate stamped cages are used, but large-size tapered roller bearings also use pin-type cages.